About RAROG

The RAROG company was established in 2023 by a team of experts with extensive knowledge and practical experience in the fields of extrusion, compounding, and the development of effective solutions for manufacturers of aluminium windows, doors and facades.

Our mission is to create high-quality and precise solutions for the thermal insulation of aluminium and steel constructions.

The company’s production facility, spanning 2000 square meters, is located in the town of Jašiūnai in the southeastern part of the Republic of Lithuania.

By the end of the second quarter of 2024, we plan to expand our production capacities, adding an additional 2000 square meters of space.

Our mission is to create high-quality and precise solutions for the thermal insulation of aluminium and steel constructions.

The company’s production facility, spanning 2000 square meters, is located in the town of Jašiūnai in the southeastern part of the Republic of Lithuania.

By the end of the second quarter of 2024, we plan to expand our production capacities, adding an additional 2000 square meters of space.

Products

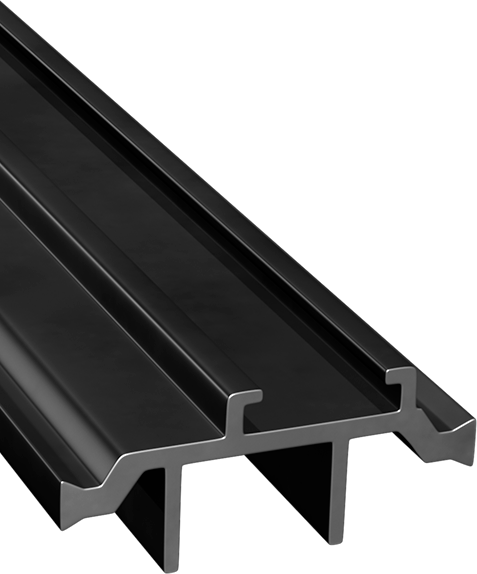

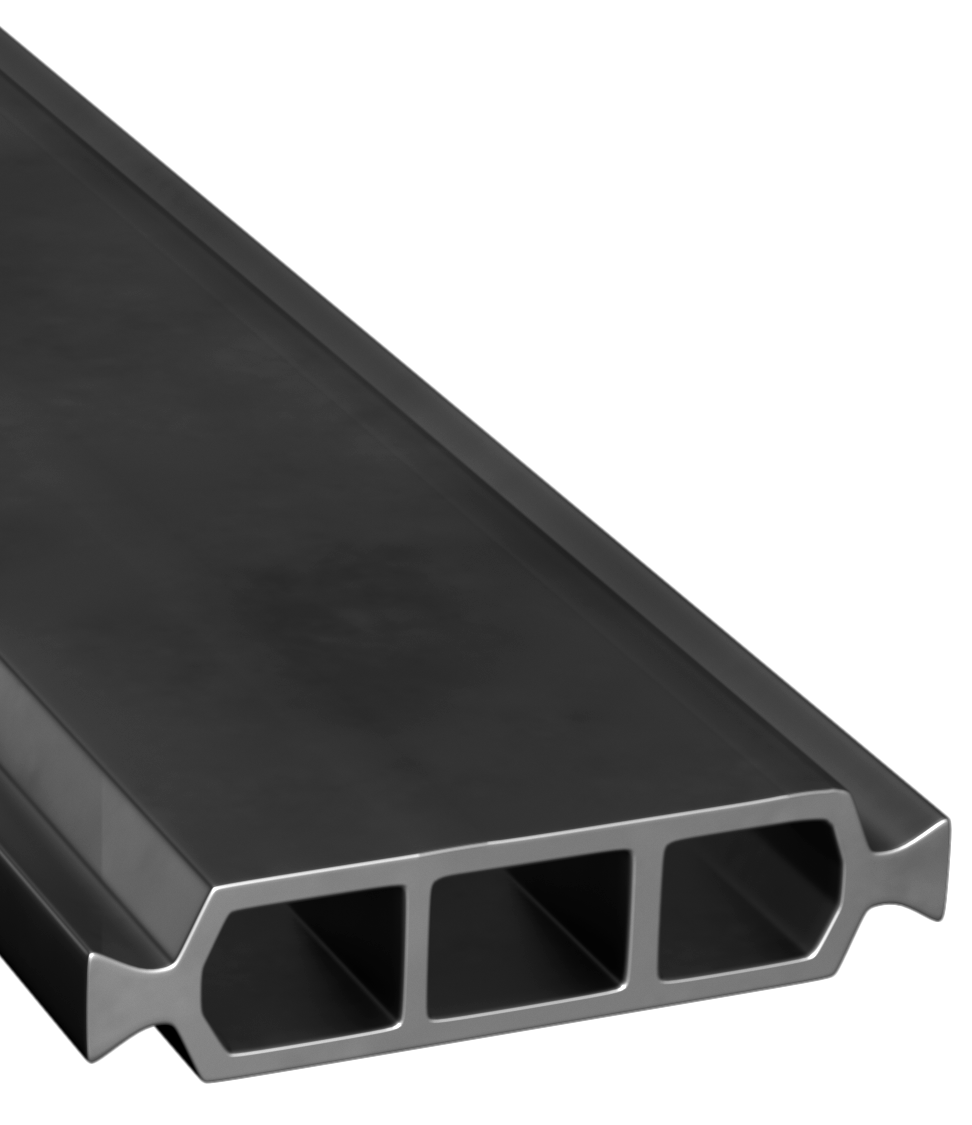

Polyamide thermal break - a time-tested solution that provides efficient thermal insulation for aluminium windows, doors, and facades.

Polyamide operating rod - a hardware operating rod for aluminium windows and doors.

Polyamide operating rod - a hardware operating rod for aluminium windows and doors.

Compound

We operate our own production facilities to manufacture PA66 GF25 compound, designed to meet our specific requirements. The high quality of the glass-fiber reinforced polyamide compound allows us to create multi-chamber profiles with complex cross-sectional geometries.

At RAROG, we highly value environmental sustainability and are committed to supporting the sustainable development of our partners. Upon customer request, our company has the capability to manufacture thermal breaks using recycled polyamide that fully complies with rigorous building certification standards. This approach promotes waste reduction and the efficient utilization of limited resources.

Every compound we produce is tested to ensure compliance with the ISO 9001:2015 Quality Management System requirements.

At RAROG, we highly value environmental sustainability and are committed to supporting the sustainable development of our partners. Upon customer request, our company has the capability to manufacture thermal breaks using recycled polyamide that fully complies with rigorous building certification standards. This approach promotes waste reduction and the efficient utilization of limited resources.

Every compound we produce is tested to ensure compliance with the ISO 9001:2015 Quality Management System requirements.

Quality control

In our dedicated in-house laboratory, we adhere to strict quality control protocols. We examine everything from the raw materials used in the composition of the compounds we produce, to the mechanical properties and linear dimensions of our finished products.

Our assessments include:

· Material density

· Glass fiber content

· Melting point and moisture absorption behavior

· Tensile strength and elongation at break (Q)

· Permanent set under load and shear strength (T)

Our meticulous attention to detail ensures that all relevant quality metrics are thoroughly inspected and documented at each stage of production - from incoming raw materials to the finished product. Moreover, we maintain a comprehensive archive of this technical data, allowing for precise tracking.

Our assessments include:

· Material density

· Glass fiber content

· Melting point and moisture absorption behavior

· Tensile strength and elongation at break (Q)

· Permanent set under load and shear strength (T)

Our meticulous attention to detail ensures that all relevant quality metrics are thoroughly inspected and documented at each stage of production - from incoming raw materials to the finished product. Moreover, we maintain a comprehensive archive of this technical data, allowing for precise tracking.